Please select your location and preferred language where available.

Smart Factory

An autonomous intelligent factory that leverages artificial intelligence (AI) and the Internet of Things (IoT)

BiCS FLASH™ and other flash memories are fabricated at Yokkaichi Plant, a smart factory that incorporates a broad array of cutting-edge technologies. Big data are collected from manufacturing and test systems and analyzed using machine learning and other AI technologies so as to enhance productivity.

Interview

A massive, constantly evolving smart factory powered by three billion data points and AI: The Yokkaichi Plant of KIOXIA is at the forefront of flash memory innovation.

As the rapid expansion of AI makes data more valuable than ever, the role of flash memory is becoming increasingly important. To make the best use of the AI technologies of machine learning, deep learning, and generative AI, collecting and analyzing data are essential. The demand for flash memory to store such valuable data, the starting point for all AI applications, grows in parallel with the rapid development of AI. Flash memory is produced at the Yokkaichi Plant of KIOXIA Corporation in Yokkaichi City, Mie Prefecture.

Building innovation on 3 billion data points and AI: KIOXIA’s Yokkaichi Plant takes on the challenge of state-of-the-art manufacturing

One of the world's largest flash memory factories, KIOXIA’s Yokkaichi Plant is also a massive smart factory that uses AI technology and the 3 billion data points it generates every day to manufacture cutting-edge products. While the use of AI is currently spreading across many different technology sectors, it has long been a standard part of operations at the Yokkaichi Plant. Here is a closer look at various initiatives promoted at the Plant, where many engineers understand and use AI to produce high-quality flash memory.

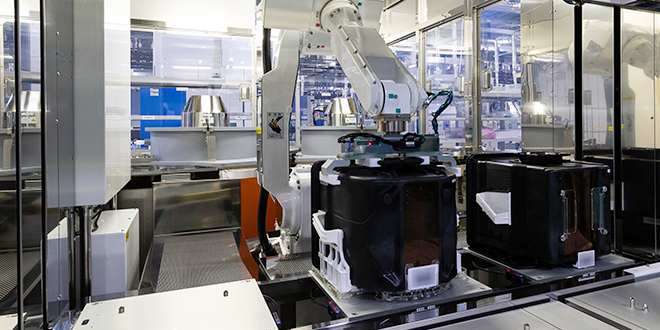

Automated Cleanrooms

All the processes and inter-process transport in a cleanroom are fully automated using a production management system. Automated guided vehicles (AGVs) are utilized in the cleanroom to transport workpieces. Manufacturing systems perform a sequence of processing operations automatically. When one process is completed, the workpieces are collected again by AGVs and transported to the next one.

Lower: A product collected by the OHT from manufacturing system

IoT Infrastructure and Big Data

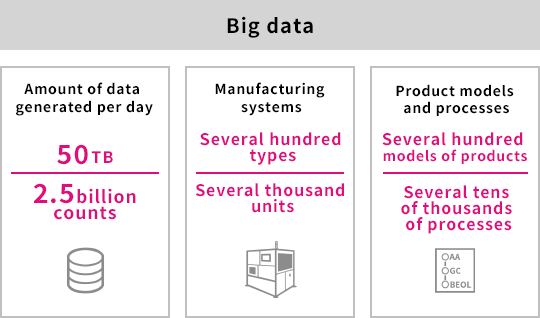

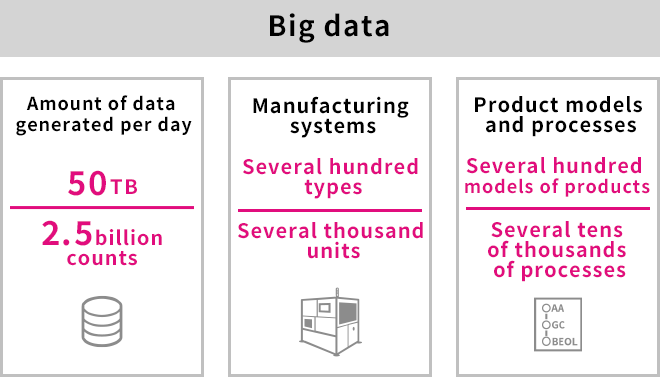

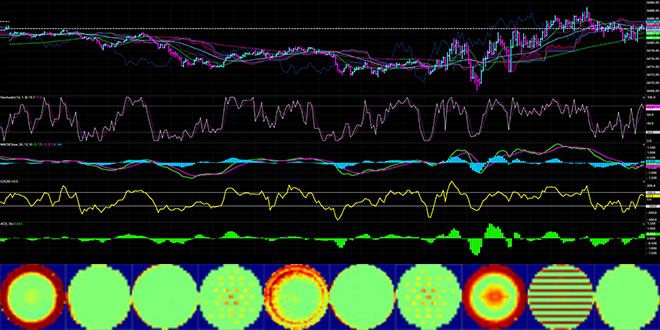

At Yokkaichi Plant, several thousands of process and inspection/measurement tools generate more than 3 billion data every day, which are mainly related to the results of sensing, tests, and measurements. All these data are collected into a massive integrated database and analyzed for the purpose of improving productivity.

Incorporating Apache Hadoop, Apache HBase, Apache Spark*, and other cutting-edge big data software tools, our big data solution has received awards from big data companies in Silicon Valley.

- Apache Hadoop, Apache HBase, and Apache Spark constitute an open-source software framework for distributed large-scale data processing.

A huge amount of manufacturing data generated at a fab is collected, structured, and stored for big data analytics.

Sophisticated AI-based Analysis

A semiconductor memory fab is a large-scale plant consisting of several thousand tools that process nanoscale devices. Utilization of data is crucial to quickly grasp what is happening at the micro and macro levels. However, the amount of data is too huge for humans to handle without the assistance of technology. Therefore, we have been working to enhance the sophistication of big data analysis using AI and machine learning technology, continually improving our capability to infer the root causes of device failure and detect signs of defects automatically.

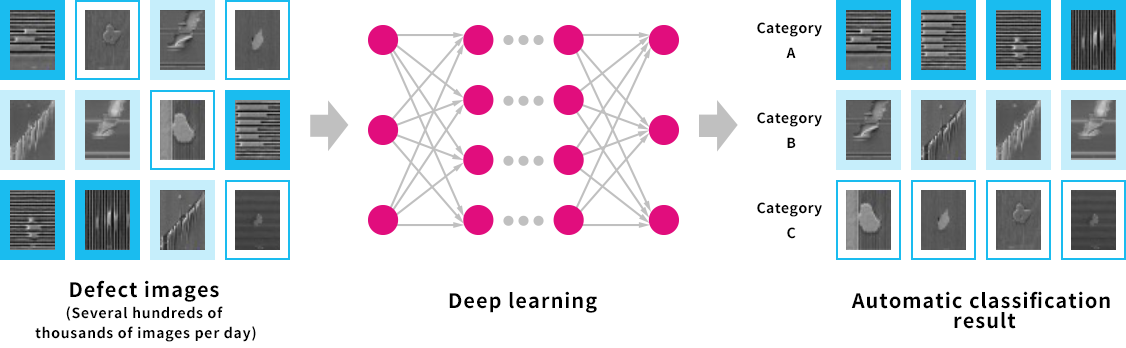

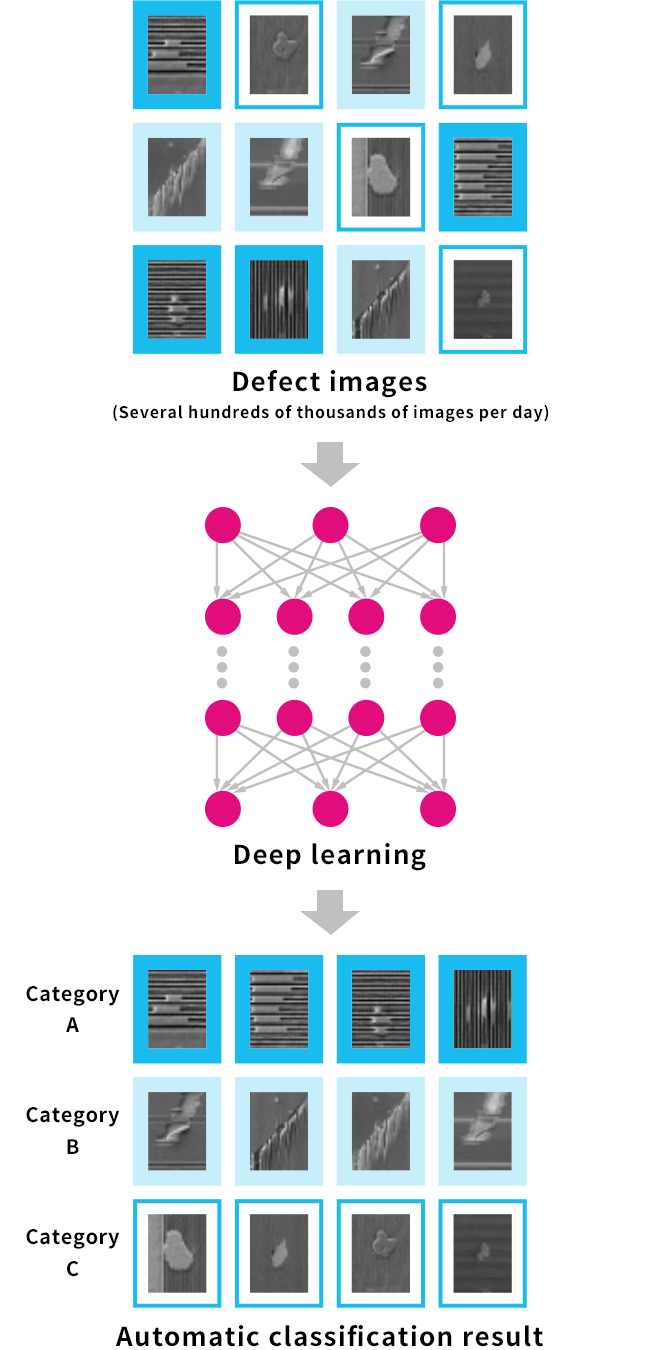

Image Classification Using Deep Learning

At Yokkaichi Plant, we are working on AI and machine learning, particularly deep learning technology, to automate the processes that have conventionally relied on human senses. For example, deep learning is employed to classify the defects detected by inspection tools. It is no easy task for human engineers to classify several hundreds of thousands of images every day. Therefore, we employ an automatic deep learning-based method to enable prompt identification of the causes of defects.

We have developed not only a filter-wise quantization algorithm which optimizes the number of weight bits for each one of tens or thousands of filters on every layer but also the dedicated accelerator. With these algorithm and hardware architecture, the inference time can be reduced while maintaining recognition accuracy.

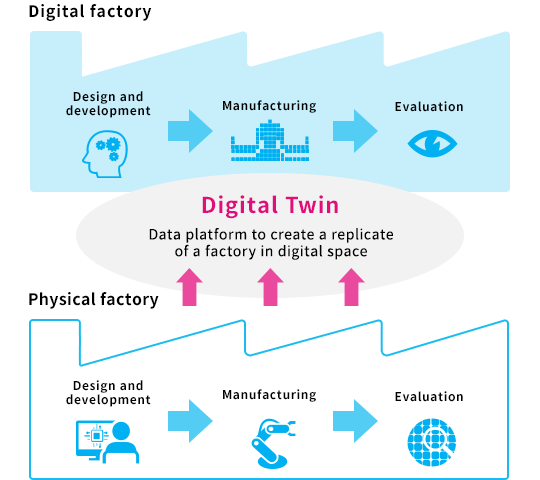

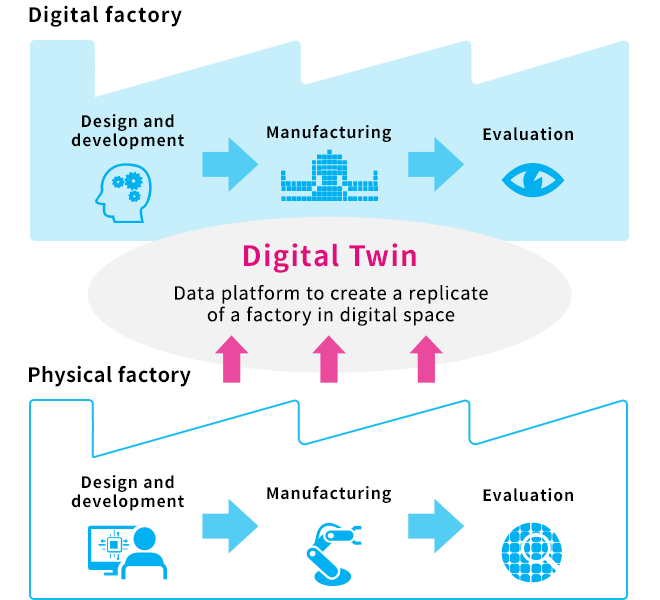

Digital Twin

A digital twin is a digital representation of a physical process that occurs at a factory. We are working on the application of digital twin for analysis and optimization. Not only sensing data from manufacturing systems and machines but also the records of human tasks, judgment results, and even text are virtualized and represented as digital twin models. In digital space, data analysis and simulation based on AI and machine learning technology are performed for optimization and prediction. Their results are fed back to the real world so as to enhance productivity and quality.

AI- and IT-related Awards

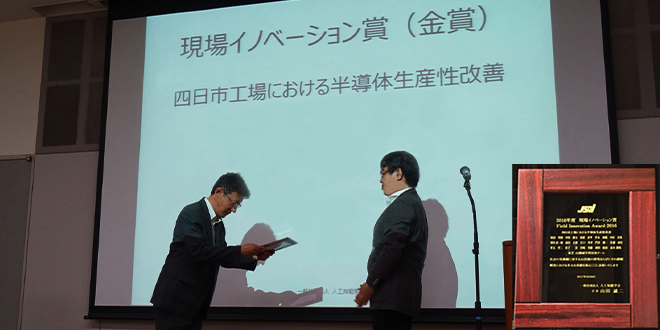

KIOXIA’s Yokkaichi Plant has been promoting the use of big data, AI, and machine learning technologies. Despite all the difficulties, we have improved these technologies and they have become essential to our business. Our initiatives in this field have received the following awards from external organizations.

The JSAI Field Innovation Award honors individuals and organizations that develop and apply artificial intelligence (AI) to issues at business sites. Yokkaichi plant improved manufacturing productivity through AI-based analysis of big data collected from manufacturing and inspection equipment.

Cloudera, which delivers a big data platform recognizes organizations utilizing big data and IoT technology to solve business problems. Yokkaichi plant generates a huge amount of manufacturing data from several thousands of units of manufacturing systems. All these data are collected into a massive integrated database and analyzed for the purpose of improving productivity.

The Advanced Equipment Control/Advanced Process Control (AEC/APC) Symposium Asia 2019, which is a forum for semiconductor manufacturing technology, honors the best research paper. KIOXIA received the award for "Robust Estimation of Mixed-Type Wafer Map Similarity Utilizing Non-negative Matrix Factorization."

Fieldwork Improvement Using IT

Even automated cleanrooms require human interventions for the repair and maintenance of equipment and in the event of product anomalies. We leverage IT technology to analyze the relevant processes so as to improve the efficiency of these tasks. Nowadays, cleanroom engineers utilize the results of the AI-based data analysis described above in order to correct manufacturing problems promptly.

- Apache Hadoop, Apache HBase, and Apache Spark are trademarks or registered trademarks of Apache Software Foundation in the U.S.A and other countries. Company names, product names, and service names mentioned herein may be trademarks of respective companies.