Please select your location and preferred language where available.

Development of Monocrystalline Si Channel Process for 3D Flash Memory

March 06, 2020

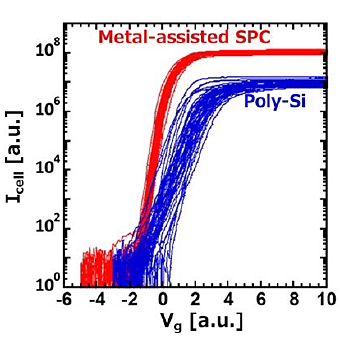

In order to increase bit density more on 3D flash memory, we have been studying the technology for highly-stacked 3D flash by increasing the number of vertically stacked word lines. The highly-stacked structures cause a performance degradation due to increased channel resistance and cell Vth variation which is derived grain boundaries in poly-Si. Monocrystalline Si channel is one of the ultimate solutions, and we tried to apply the technology forming macaroni-shaped monocrystalline Si channel in vertical memory holes. As a method of forming monocrystalline Si, we focused on the metal-induced lateral crystallization (MILC), which is a solid-phase crystallization technology using the metal such as nickel silicide studied in Si-TFT (Thin Film Transistor) as the growth edge [1]. By applying MILC technology to Si film in the vertical memory holes, we successfully fabricated the formation of monocrystalline Si from amorphous Si via nickel silicide (Fig. 1).

The 3D flash memory cell devices equipped with this technology demonstrated superior electrical characteristics and reduced variation compared to conventional devices using poly-Si as the channel (Fig.2).

This achievement was presented in the 2019 IEEE International Electron Devices Meeting [2].

References

[1] S.-W. Lee and S.-K. Joo,” Low temperature poly-si thin-film transistor fabrication by metal-induced lateral crystallization”, IEEE Electron Dev. Lett. 17, pp.160-162 (1996)

[2] H. Miyagawa, H. Kusai, R. Takaishi, T. Kawai, Y. Kamimuta, T. Murakami, K. Ariyoshi, T. Asano, M. Goto, M. Fujiwara, Y. Mitani, T.Obu and H. Aochi, “Metal-Assisted Solid-Phase Crystallization Process for Vertical Monocrystalline Si Channel in 3D Flash Memory”, 2019 IEEE International Electron Devices Meeting, pp.650-653