Please select your location and preferred language where available.

Does Memory Have Emotions?

What’s Ahead in Recording in Technology

- On the Front Lines of Memory -

October 1, 2019

The advent of NAND flash memory enabled the establishment of a lifestyle in which we can easily record information and carry it around. Amidst continuing growth in information distribution volume bolstered by the spread of the Internet of Things (IoT), the role of memory is expanding.

In any event, when progress in technology makes possible the transformation of the five senses and emotions of humans into data form, recording technology will become “memory” technology. We spoke with three engineers from KIOXIA regarding how R&D is expanding the possibilities for the future. Takuji Narumi, associate professor at the University of Tokyo’s Graduate School of Information Science and Technology served as the interviewer.

Will Recording Media Become “Memory Technology” by Getting Closer to Human Beings?

──I’d like to direct this first question to Kazunari Ishimaru, who is involved in the basic development of next-generation memory technology at the Institute of Memory Technology Research and Development. More than 30 years have passed since the birth of NAND flash memory in 1987. How do you see the technology evolving?

Ishimaru: When thinking about the future of flash memory, there are presently two primary directions I can see. One would be to investigate increasing capacity, as we have been. I’m confident that information devices and communications technology will continue to evolve, advancing steadily forward. That being the case, naturally flash memory that enables larger volumes of data to be recorded will be in demand.

The other primary direction would be the development axis of making memory “smarter” to more efficiently handle large volumes of recorded data. Flash memory, for instance, is used in conjunction with a part that plays the role of a control tower, called a controller.

Enhancing that function will allow us to more rapidly and more stably record data.

And if we make data even smarter, the memory itself will determine whether to accept or reject the recorded information, and instantly present the precise information to the user. The issue is how to capture the necessary data from large volumes of information and output it. That is one of the keys to the development of next-generation memory. We could even say that memory will take on human characteristics.

──I see. So we won’t be limited just to recording equipment.

Ishimaru: Yes, that’s right. First, memory made not from semiconductors but from some completely new material may be developed. At a recent academic conference, research was presented concerning the recording of data on DNA. It’s an outrageous idea, but once 20 years have passed it may very well have come true.

Personally, I imagine that someday, things will be able to remember information. For instance, wouldn’t it be fascinating if the fountain pen used by legendary writer Soseki Natsume when he wrote I Am a Cat had remembered everything from that time? We would be able to read not just the contents of the novel, but his feelings and the conditions in which he was writing. And new works would emerge from the writing stroke of Soseki, which the pen would have learned, which really excites me when I think about it. It may be a distant dream, but I would love to take on the challenge of developing memory that could convey sensory information such as human emotions and the five human senses that accompany the recorded data.

──As I listened to you speak, I recalled the “Shikinen Sengu” ritual, or periodical renewal—where a new shrine is constructed—at Ise Grand Shrine. Every 20 years, a new shrine is erected and the God who rests there is moved. But the objective is not simply to “store” the thing. I think there is great meaning in the succession of the shrine construction technology and the ceremony procedures to humans in an active way. Even among researchers involved in virtual reality (VR), which is my area of specialty, ways to record and pass on people’s experience and skills are actively discussed.

Ishimaru: I see. The Shikinen Sengu is a framework for handing down human experience and skills. If we apply this principle to memory, it would probably be good to add functions that are close to human characteristics. For instance, having the memory be able to determine that a particular user has a poor memory, and copy a set of data for them. Memory itself will likely come to more closely resemble human beings.

Automated Manufacturing Processes are Responsible for Social Implementation

──Moving on, I’d next like to pose a question to Hidenori Kakinuma, who is involved in activities to improve flash memory manufacturing bases. Please tell us how NAND flash memory is made, and share with us a bit about the manufacturing process.

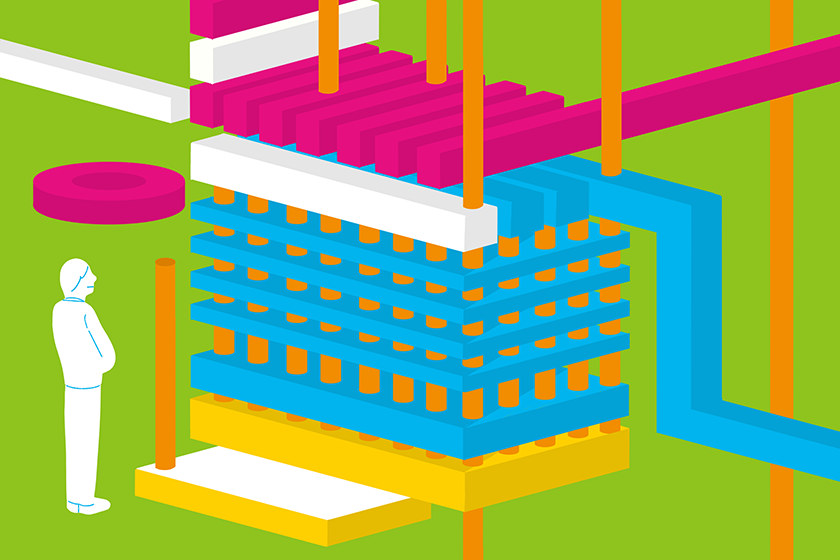

Kakinuma: Today, NAND flash memory, which has spread worldwide, is made by etching precise electronic circuit patterns (original plate) onto silicon wafers. The process overall is microfabrication, or extremely precise and complex nanometer-level fabrication. The site area of our Yokkaichi Plant, which is the world’s largest flash memory manufacturing base, measures nearly 50 hectares and incorporates five clean rooms, or rooms where the air is constantly purified. The facility also has more than 7,000 pieces of manufacturing equipment of about 200 different types. Work that is done in clean rooms at manufacturing sites is almost completely automated—you will very rarely see people there. There are people in other rooms managing the clean rooms by sending instructions via automated systems, or confirming operational status.

Looking at flash memory mass production, the substantive issue is how low we can keep production costs while still producing high-quality products. In mass producing cutting-edge new products, we rack our brains figuring out how to increase yield, whether there is any waste, and how to raise productivity.

*Yield: The quantity of products manufactured in contrast to the volume of raw materials used. If the yield is 100%, that means there were no defective products, and that all raw materials went into the products.

──Can you provide details on any measures being taken to enhance efficiency?

Kakinuma: One major change that has taken place over the past several years is the utilization of big data. At our Yokkaichi Factory, more than 2 billion pieces of data are generated by our manufacturing equipment and automated systems each day. This is the essence of big data, and while it is being used in real time, it is also being accumulated into a database. We are applying it to factory management and problem solving and analysis by making the data visible in the form of numeric tables and graphs.

What’s more, recently, we are undertaking various AI initiatives by combining big data with AI. For instance, in order to monitor defects on silicon wafers during production, more than 300,000 images are taken a day with an electron microscope. When inspecting for defects using image data, with a traditional system assembled by humans, the automatic classification rate is 50%, which means that humans have to do visual inspections on the remaining half. When we adapted AI to this task, the automatic classification rate increased to over 90%. This means that the work volume for human beings decreased to one-fifth what it previously was. AI is much better suited for this kind of image inspection and big data analysis than human beings. The automation in this genre through AI is expected to continue.

──Big data and AI utilization methods are being actively discussed in various fields. What does the future look like to you?

Kakinuma: By using big data and AI at our Yokkaichi Plant, we hope to find solutions to how we can achieve comprehensive optimization, such as improving the operational efficiency of our equipment, and the return from our investments in production equipment, given that a single piece of equipment can cost hundreds of millions of yen. That will lead to us being able to provide flash memory effectively and at low cost. Then, through automation, we hope to gradually reduce the burden of work that humans are not adept at, and allocate those human resources to more advanced fields where they can be useful in creating new value.

We are proceeding with automation in areas where humans do not need to intervene. In areas where we don’t have past data or knowledge, however, AI in its present state is insufficient. New discoveries and technologies are constantly demanded from flash memory. I see a future of autonomous AI—not that it replaces humans, but to autonomously determine what is in pinpointing optimum solutions while cooperating with them.

On the Front Lines of Development in Preparation for Further Information Explosion

──Next, I’d like to address Yuichiro Murahama, who is pursuing device development at the Advanced Memory Development Center while looking several years into the future. How has the development of NAND flash memory changed over the past 10 years?

Murahama: Above all, the speed of development has increased dramatically. Three-dimensional, or 3D flash memory, which is currently our main product, was invented in 2007. After that, we went to market with the 48-layer stacked cell BiCS FLASH™, or BiCS2. That was followed in 2017 by the 64-layer BiCS3, and the 96-layer BiCS4 in 2018. As time passes, we are continuing to increase recording capacity.

In the past, updating by one generation took four to five years. Now that’s down to about a year to a year and a half. That’s how quickly the specifications demanded of memory—reliability, speed performance, low power consumption, and cost—have increased. By establishing a structure that enables R&D of other things in parallel with the flash memory of that time, we have made possible the present development cycle where we are normally able to respond to societal demand in a year or two.

──So, in line with the demand in recent years, you have evolved toward increased capacity by increasing the number of layers. How far do you think you can increase 3D flash memory capacity (number of layers)?

Murahama: We’re not exactly certain, but at the academic conference, there were researchers who were sure that 500 to 800 layers were possible. For the time being, it’s clear that we can increase capacity by increasing the number of layers. The development of 3D flash memory, however, requires nanometer-level processing technology, so it doesn’t move in a straight line. In manufacturing the BiCS4, for instance, in a silicon wafer 30 centimeters in diameter, over one trillion precise holes that are 100 nanometers in diameter, or about the size of a virus, and 50 times that—or 5,000 nanometers—in depth are opened.

──So, tremendously sophisticated technology is necessary.

Murahama: Yes, you’re right. But I feel like human beings are progressing as well. Young engineers, in particular, are very capable these days, and are much better at their jobs than I was at that age (smiles). The development environment for tools and other things has gotten remarkably better, but even without that, I feel like there are many engineers today who can do their work more efficiently than we did a long time ago. And when I spend time at a development site, I feel technology is progressing through the accumulation of human effort and ingenuity.

Regardless of how far technology evolves, at the end of the day, new ideas can only be generated by human beings. And in many cases, ideas that surmount challenging problems emerge from casual discussions in a horizontal structure. I want to make sure junior engineers understand the importance of horizontal relationships as the basis of technology development.

From Recording to Memory: Differences in Relationships Generate Differing Values

──I’d like to return to Mr. Ishimaru for my final point. Listening to you today, it’s clear to me that the feelings of engineers involved in R&D are very strong.

Ishimaru: I’ve always thought a passion for technology was necessary for development. The paper on NAND flash memory was released in 1987, and it was around 2000 when it began to become widely used. And the 3D flash memory paper was released in 2007, but mass production has just begun within the past few years. This tells us that it takes about 10 years from the invention of a single technology until it becomes popular as a product. I have made it my job to serve a purpose in development that ascertains the trends of the times before it spreads across the world.

That said, it is rather difficult to forecast what society will be like 10 years from now. But by following discussions at academic conferences, and by looking at a product through to the finish as a user who jointly participates in open innovation with universities, I’m trying to anticipate future needs.

──Along with big data, which has become very common, research is proceeding on deep data, which encompasses all information on a single person. If realized, we should be able to forecast that person’s future, including consumption behavior and diseases they would be susceptible to. If data connects with individuals, a transformation in values could occur where data which had until now been regarded as useless will be recognized as treasure.

Ishimaru: I agree. In that sense, we will have to take a look at the relationship between digital data and human beings. When that data was recorded, what did it mean to that person? And what kind of emotions does that data evoke today? The desire to value this perspective is also incorporated in the brand catchphrase, which from “recording devices” that simply accumulate data to “memory devices” that stir people’s hearts.

──There is a significant gap, however, between “recordable” and “conveyable.” For instance, media art lost by a device 20 years ago cannot be regenerated, and a service that had been offered on the cloud can no longer be used once it ends. The engineers involved in the development of memory must really deal with the issue of reproducibility.

Ishimaru: I would say that’s true. For digital recording media, the topic of how to overcome degradation over time and changes in the environment to maintain reproducibility is a major issue. For instance, just as with cell division, before recording media deteriorates or wears out, if we can leave a shadow behind by creating a next-generation copy, it may very well resolve that issue.

Going forward, I want to be involved in product development while considering a better interface between memory and human beings. I’d love to create memory that can convey 50 or 100 years’ worth of memories.

Kazunari Ishimaru

Senior Fellow

Institute of Memory Technology Research & Development

IEEE Fellow

Since joining Toshiba in 1988, Ishimaru has pursued the development of various types of memory including new memory, and advanced CMOS technology. He currently oversees R&D strategies and open innovation. He served as a visiting researcher at the University of California, Berkeley from 1997 to 1998. Ishimaru became a member of the Institute of Electrical and Electronic Engineers (IEEE) Electron Device Society board in 2019.

Hidenori Kakinuma

Chief Specialist

Digital Process Innovation Center

Digital Process Advanced Laboratory Group

Kakinuma joined Toshiba in 1985 and has been involved in development work for semiconductor manufacturing systems. Today, as the leader of an AI machine learning project, he is promoting the utilization of AI in enhancing productivity.

Yuichiro Murahama

Senior Manager

Advanced Memory Device Development Department

Advanced Memory Development Center

Since joining Toshiba in 1990, Murahama has been involved in various phases of the commercialization of memory, from development to factory production rollout. Today, he pursues next-generation flash memory product development at the Advanced Memory Development Center.

Takuji Narumi

Associate Professor, Graduate School of Information Science and Technology

The University of Tokyo

Born in Fukuoka Prefecture in 1983, Narumi graduated from the University of Tokyo’s Faculty of Engineering in 2006, and completed the doctoral course at the university’s School of Engineering in 2011. In that same year, Narumi was named assistant professor of the Graduate School of Information Science and Technology, and was appointed to his present position in July 2019. He is a proponent of ghost engineering, which supports the free design of our “ghost” (emotion, recognition, thought) by aggressively utilizing changes in mental state through experiencing an extension of the human body. Among Narumi’s achievements are a Best Paper Award from The Virtual Reality Society of Japan (VRSJ), an award through the Ministry of Economy, Trade and Industry’s (METI’s) Innovative Technologies program, and a Good Design Award.

Author: Yoshiaki Aizawa

Illustration: Yukihiro Takeda

The content and profile are current as of the time of the interview (October 2019).