Please select your location and preferred language where available.

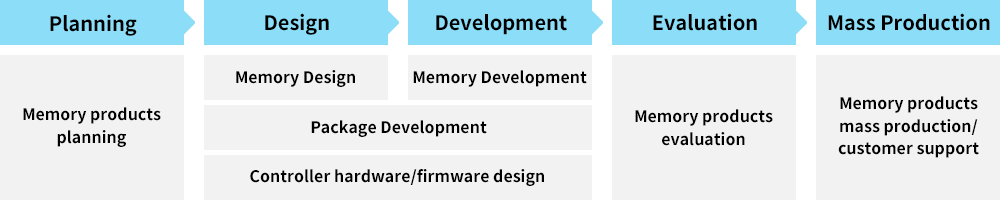

KIOXIA's Product Development Process

KIOXIA covers from R&D to mass production of flash memory and SSD products. Introducing the mechanisms of technological innovation, that is, how R&D is conducted in the process of bringing our products to market.

Memory Development

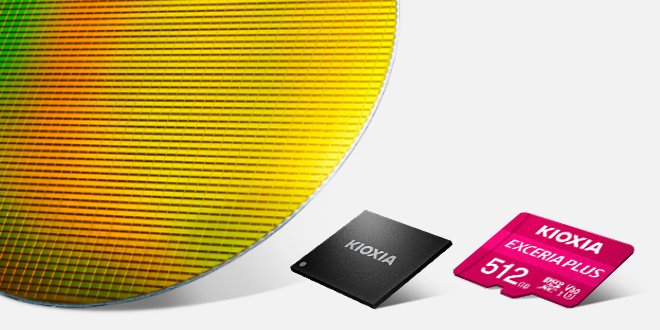

KIOXIA offers memory chip and flash memories with integrated controller chip in one package (managed flash.) Managed flash includes embedded flash memory products such as e-MMC and UFS, as well as SD memory cards and USB flash drives.

Planning

- Product marketing

- Customer's requirements/market/technological trends research

- Product planning

The product planning team develops product specifications incorporating customers’ requirements, by considering marketing strategies and initiate product development. It also offers proposals with total solutions including technical support and sales assistance to customers worldwide.

Design/Development

Memory Design

- Circuit/layout design

- System design

- Mask tooling/analyze/evaluation

The memory design team develops new circuit technologies and create memory designs to reduce chip area, ensure reliability, increase operating speed, and reduce power consumption based on the specification of memory product. It also performs a wide range of tasks from system design, detailed circuit design, and layout to the evaluation and analysis of prototype chips. In addition, the team is also responsible for design technology related to lithography to form layout patterns on wafers with high accuracy.

Memory Development

- Device development

- Integration process

- Inspection/measurement and electrophysical analysis

The memory development team designs and evaluate memory devices in collaboration with the production team. It develops super-small-geometry and super-high-performance unit processes, cutting-edge test and measuring technologies for next-generation memory devices to establish process recipes for next-generation and post-next-generation memory devices.

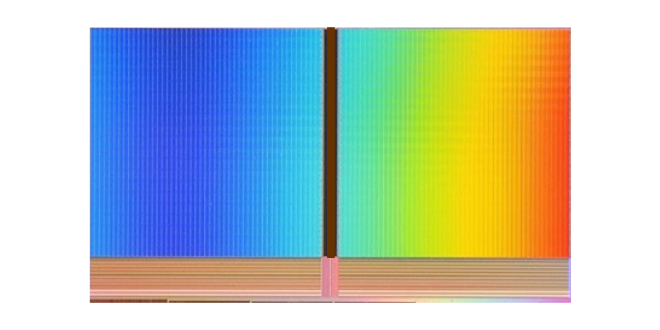

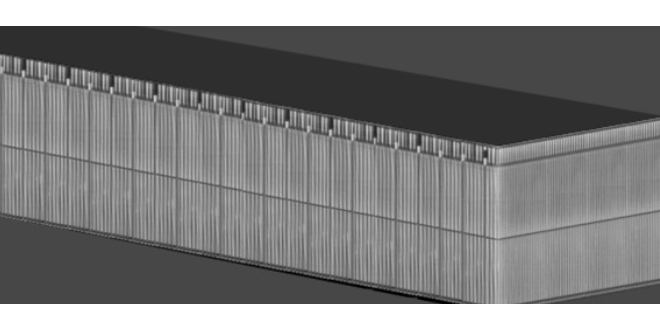

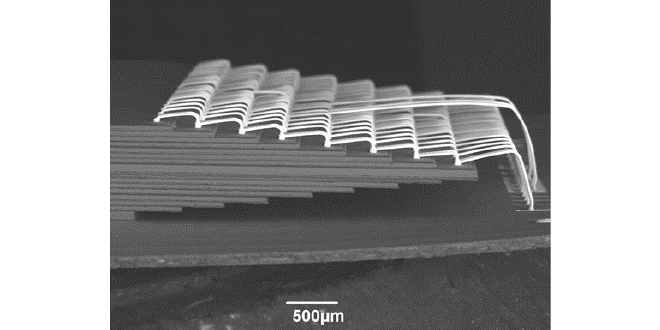

Package Development

- Package design/development

- Small and thin package technology

- 3D stacked package technology

The package development team not only designs the package mechanical design substrate wiring design, but also examines the machining mechanical strength and thermo-electrical design, as well as assembly process development.

Packages protect semiconductor chips, and increases the capacity and function of memory devices through 3D multi-layer chip stacking and controller chip integration.

Controller hardware/firmware design

- Hardware design/development

- Firmware design/development

The controller hardware/firmware design team develops LSI chips that bridge between memories and host computers.

These control whole NAND system with cutting-edge hardware and firmware, incorporating technologies such as bad-block management, error correction, logical-to-physical address translation, write leveling, speed improvement, encryption, and power consumption reduction.

Evaluation

- Test system development

- Electrical characteristics evaluation

- Reliability testing

The evaluation team establishes schemes for the performance evaluation and shipping test of prototype and production devices. At the development stage, the evaluation team provides feedback to the design and process teams for the improvement. At the manufacturing stage, the evaluation team is responsible for delivering only conforming devices to customers.

Mass Production

- Productivity improvement

- AI/machine learning

At KIOXIA, products are fabricated with cutting-edge technologies that contribute to higher quality and stable production with high yield rate. For example, Big data from manufacturing and testing equipments are analyzed using AI techniques to improve productivity and foster technological innovation for BiCS FLASH™ manufacturing.

The production team grasps customers’ applications of our products with the aim of proper quality management.

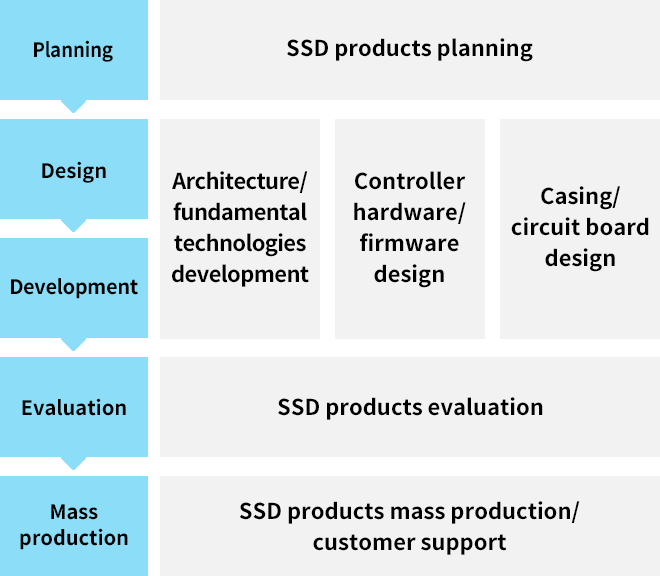

SSD/Memory Cards Development

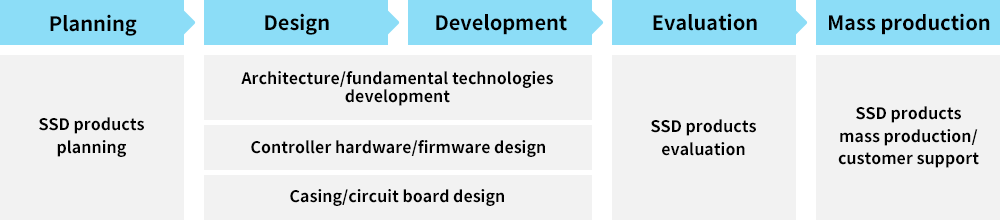

Planning

- Product marketing

- Customer's requirements/market/technological trends research

- Product planning

The product marketing team develops business strategies based on analysis of the expanding IoT and cloud markets.

It plans product specifications including interfaces and form factors based on customer requirements and market research. The team provides comprehensive solution proposals, including software as well as hardware, to domestic and international customers.

Design/Development

Architecture/fundamental technologies development

- SSD architecture

- Product security technology

- NAND control technology

KIOXIA develops SSDs for three segments: consumer, data center, and enterprise applications. Each segment has a different SSD architecture and we develop separately. On the other hand, we are actively promoting the development of common IP for the core components of products with high commonality, such as NAND control (e.g., bailout methods and error correction technology) and security technology (authentication and encryption technology), in order to increase efficiency.

Controller hardware/firmware design

- Hardware design/development/prototyping

- Firmware design/development

The controller hardware/firmware design team develops LSI chips that bridge between memories and host computers.

These control whole NAND system with cutting-edge hardware and firmware, incorporating technologies such as bad-block management, error correction, logical-to-physical address translation, write leveling, speed improvement, encryption, and power consumption reduction.

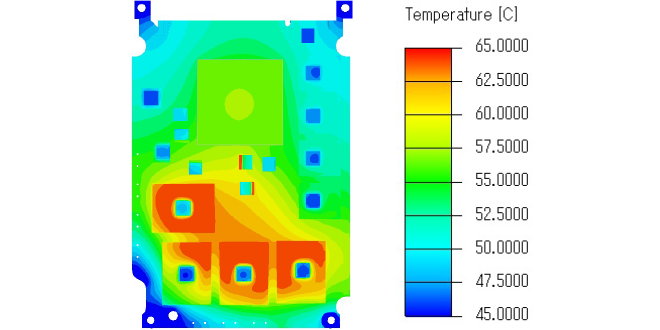

Casing/circuit board design and development

- Thermo-fluid and structural analysis, casing design

- Substrate wiring design, component selection

- Mounting technology

Based on electrical, thermal, structural, and other analysis, the team develops hardware components in SSDs including casing design, component selection, and board wiring design called artwork.

Evaluation

- Hardware/firmware evaluation

- Test system development

- Reliability testing

The evaluation team establishes schemes for the performance evaluation and shipping test of prototype and production devices. At the development stage, the evaluation team evaluates function, performance, stability and interoperability of prototypes and provides feedback to the design and process teams. The team also conducts reliability tests for quality assurance.

Mass Production

- Manufacturing technology

- Automation system technology/Manufactring system development

SSDs consist of a huge number of components. In mass production, all of these components are soldered onto the board. The team is also responsible for the development of manufacturing systems related to production and the development of global locations. In addition, it is also involved in efforts to support maintenance and operations for customers.